Repairing Commercial Refrigeration Repair Service: Techniques for Quick and Effective Fixes

In the world of business refrigeration, the requirement for swift and exact troubleshooting strategies is vital. When a refrigeration device malfunctions, the repercussions can be turbulent and expensive to service operations. Comprehending the common problems that pester commercial refrigeration systems and having a toolkit of diagnostic techniques at your disposal can make all the distinction in swiftly determining and correcting troubles. As we navigate with the intricacies of repairing commercial refrigeration fixing, we will certainly uncover the essential approaches for fixing problems successfully, making certain that companies can maintain ideal air conditioning efficiency and reduce downtime.

Common Business Refrigeration Concerns

Industrial refrigeration systems generally experience a variety of operational problems that can disrupt their efficiency and performance. One common issue is inappropriate temperature control, which can result in food perishing and waste otherwise without delay attended to. This trouble might come from problems with the thermostat, evaporator follower, or condenser coils, requiring detailed evaluation to identify the origin. Another common problem is inadequate air flow, usually triggered by clogs in the vents or a malfunctioning fan. Poor airflow can bring about temperature inconsistencies within the fridge or freezer, affecting the high quality and safety of kept items.

Furthermore, cooling agent leakages present a substantial issue as they not just affect the cooling capacity of the system however additionally contribute to environmental injury. Regular cleansing and upkeep can assist stop this problem and prolong the life expectancy of the refrigeration system.

Diagnostic Tools and Techniques

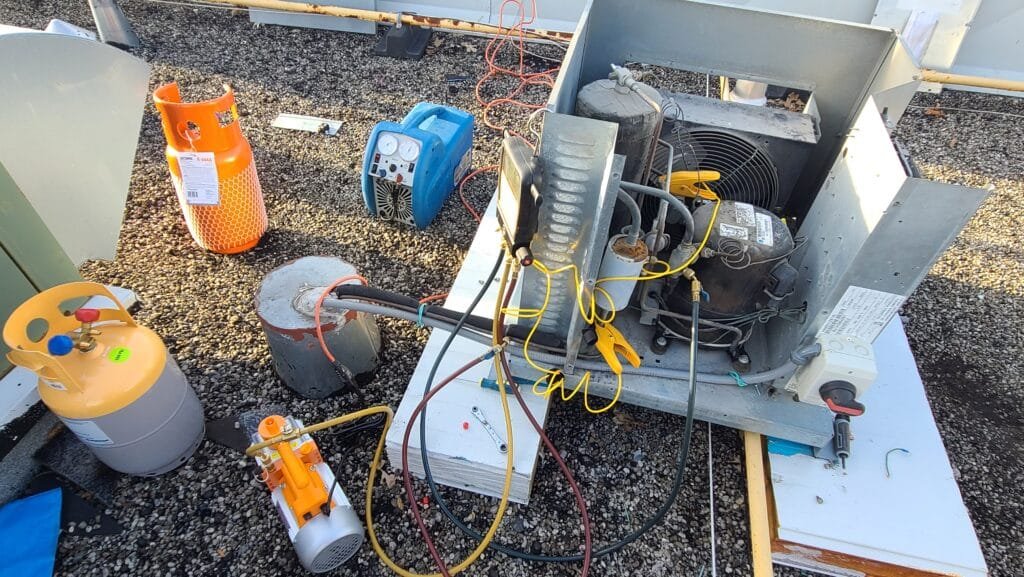

Effective troubleshooting of industrial refrigeration systems depends greatly on utilizing specialized diagnostic devices and methods to identify and solve underlying issues effectively. One vital analysis device is the multimeter, which assists service technicians determine voltage, current, and resistance in various elements such as compressors, motors, and thaw heaters. Thermometers are additionally essential for examining temperature level differentials across the system to identify prospective issues like cooling agent leakages or improper air flow. Furthermore, leakage detection devices like digital leak detectors or ultraviolet dye kits are vital for situating cooling agent leakages that can lead to system inefficiencies.

If the system has the right refrigerant fee and identify any leakages,Methods such as pressure screening using manifold gauges can determine. Visual examinations of parts for indications of ice, corrosion, or wear accumulation are also basic in detecting concerns. In addition, data loggers can be utilized to keep an eye on system performance with time and detect patterns that might show repeating troubles. By combining these diagnostic tools and techniques, professionals can successfully troubleshoot industrial refrigeration systems and supply fast and precise repair work, reducing downtime and guaranteeing ideal system efficiency.

Quick Solutions for Refrigeration Issues

When faced with refrigeration problems, professionals can execute quick repairs to resolve typical problems swiftly and successfully. If the refrigeration unit is not cooling down properly, checking and readjusting the thermostat settings might provide a fast option prior to more thorough troubleshooting is required. By applying these quick solutions, professionals can resolve usual refrigeration troubles effectively and maintain commercial refrigeration systems running efficiently.

Preventative Upkeep Tips

Implementing a positive maintenance routine is critical for guaranteeing the long life and optimal performance of business refrigeration systems. more info here Routine upkeep not only assists see this site avoid expensive breakdowns however also ensures that the devices operates successfully, conserving energy and reducing overall operating prices. Right here are some preventative maintenance pointers to keep business refrigeration systems running smoothly:

Check and Change Filters: Dirty filters can limit air movement, making the system job tougher and potentially causing damage. Check and change filters regularly to stop concerns.

Inspect Seals and Gaskets: Leaky seals and gaskets can cause temperature level variations and energy waste. Inspecting and changing damaged seals can assist preserve constant temperatures.

Expert Assistance and Services

To maintain the ideal performance accomplished through regular preventative upkeep, looking for professional assistance and solutions for commercial refrigeration systems is important. Specialist professionals have the knowledge and specialized understanding required to identify and address complex concerns successfully. When facing difficult refrigeration issues, counting on professional assistance can save both time and money over time.

Expert services offer advantages such as accessibility to advanced tools and tools, guaranteeing that repair work are lugged out effectively. Additionally, professionals are educated to comply with industry guidelines and safety and security standards, reducing the threat of crashes and ensuring conformity with lawful needs.

Final Thought

In conclusion, repairing business refrigeration repair work requires a methodical approach to identifying common problems, making use of diagnostic tools and methods, carrying out fast fixes, and focusing on preventative upkeep. Specialist support and services might be essential for more complicated troubles - commercial refrigerator repair. By following these approaches, companies can guarantee their refrigeration systems operate efficiently and successfully, minimizing downtime and prospective losses

Recognizing the common problems that pester business refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the difference in quickly identifying and treating troubles.Effective troubleshooting of business refrigeration systems relies heavily on making use of specialized analysis devices and techniques to recognize and settle underlying concerns effectively. By combining these diagnostic devices and methods, specialists can successfully repair business refrigeration systems and give fast and precise repair work, decreasing downtime and ensuring optimum system efficiency.

By carrying out these quick repairs, service technicians can attend to typical refrigeration problems efficiently and maintain commercial refrigeration systems running smoothly.

In addition, specialist assistance can help prolong the life-span of business refrigeration systems by identifying prospective concerns before they escalate.